Mass production

A unified system of computer-aided design and production facilities allows us to introduce innovations and carry out mass production for global companies in the oil and gas sector. The production area is 16 500m2. The plant is equipped with 125 units of equipment, 21 of them are high-tech. Specialists have mastered more than 100 technological operations.

Annual capacity

We produce more than 2,000 objects of the urban environment

3-5 complex parametric products

We complete a 10-million city with street furniture

We master the production of more than 10 new unique objects and products

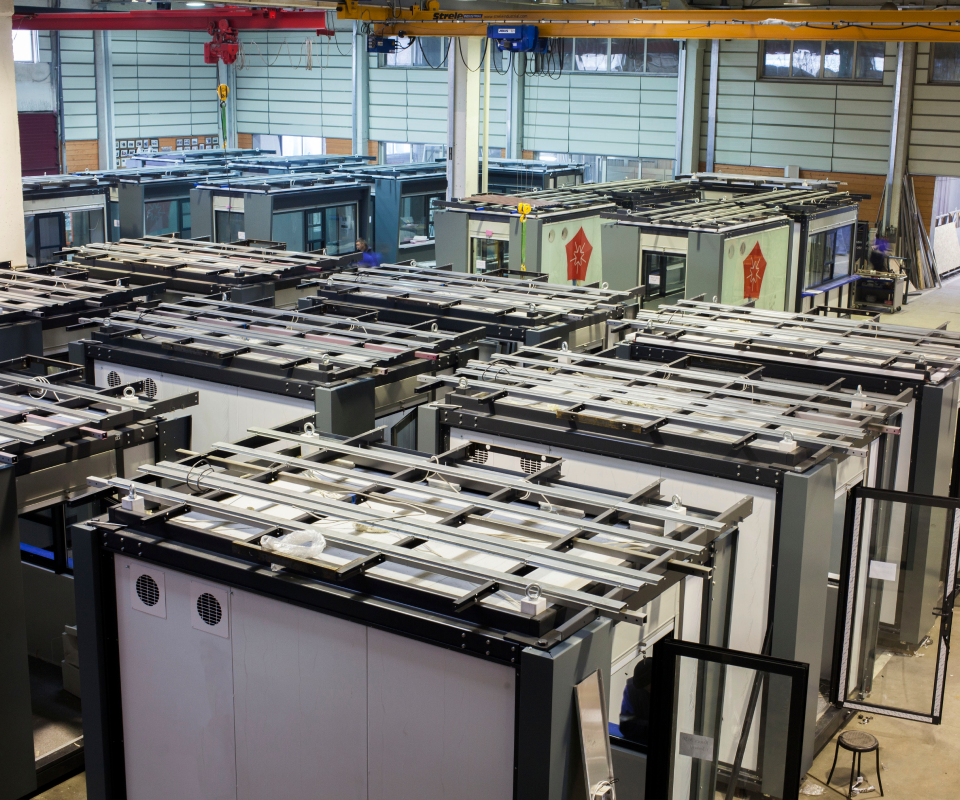

Assembly line

Technological developments and experience in the production of structures of modular type with no foundation ensures the production of up to 200 units per month on an assembly line

Thermal vacuum sublimation

The technology allows to create decorative polymer coatings, the coating has increased resilience to external atmospheric effects and resistance to detergents, chemical and mechanical impact

Sheet metal bending on robotic centre

It allows to provide serial and mass production of standardized products. Automatic panel bending appliance Salvaginini P4XE-3125 provides processing speed 2 times higher than traditional sheet bending

Powder coating on an automated line

The automated line from the leading European equipment manufacturer IDEAL LINE (Denmark) allows us to carry out industrial painting and drying of series of products made of metal, wood and synthetic materials

Welding

We carry out structural welding with the use of welding equipment from the European manufacturers such as ESAB (Sweden), FRONIUS (Austria), WM HighTec Welding GmbH and LORCH (Germany)